સપ્ટેમ્બર . 01, 2024 21:56 Back to list

Cutting HDPE Sheets - High-Quality Custom Solutions

A Guide to Cutting HDPE Sheets

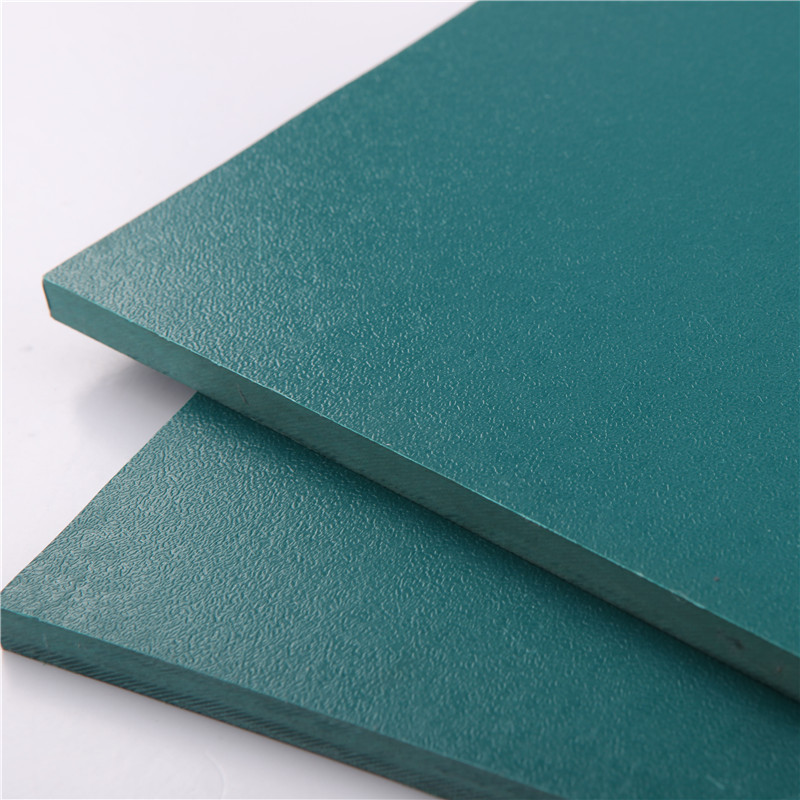

High-Density Polyethylene (HDPE) sheets are versatile materials widely used in various applications, including construction, manufacturing, and even artistry. Renowned for their durability, chemical resistance, and ease of maintenance, HDPE sheets are the material of choice for many projects. However, cutting these sheets requires some consideration and the right tools to achieve precise results. This article will provide guidance on how to effectively cut HDPE sheets for your specific needs.

Understanding HDPE

HDPE is a type of thermoplastic made from petroleum. It is known for its high strength-to-density ratio, making it lightweight yet robust. Due to its excellent resistance to impact and chemicals, HDPE is ideal for producing containers, barriers, and various industrial applications. Before cutting, it’s important to select the correct thickness of HDPE sheet based on your project requirements, as this will influence the cutting technique you should use.

Tools for Cutting HDPE Sheets

When it comes to cutting HDPE sheets, the choice of tools is crucial. Below are some commonly used tools

1. Utility Knife For thinner sheets (up to 1/4 inch), a utility knife may suffice. Make a series of scored lines on one side before snapping the sheet along the cut.

2. Jigsaw Ideal for more intricate cuts and curves, a jigsaw equipped with a fine-tooth blade works well for cutting HDPE sheets. It’s essential to set the speed correctly to avoid melting the plastic.

3. Circular Saw For thicker sheets, a circular saw with a fine-tooth blade is recommended. This tool offers a clean cut and is efficient for larger sheets.

4. Table Saw For precise straight cuts and managing larger sheets, a table saw is an excellent choice. Always use a blade designed for cutting plastics to prevent the sheet from melting.

5. Router This tool can be used to create edges or grooves in HDPE sheets and is particularly useful for decorative applications.

cutting hdpe sheets

The Cutting Process

Before you begin cutting, it's essential to prepare your workspace. Ensure you have ample lighting and a flat, stable surface to support the HDPE sheet. Here are general steps to follow

1. Measure and Mark Use a ruler or measuring tape to measure the required dimensions. Mark these measurements clearly with a marker.

2. Secure the Sheet Clamp the HDPE sheet down to prevent it from moving during cutting, which can lead to inaccuracies.

3. Cutting Technique Depending on the tool you are using, follow the appropriate cutting technique (straight lines for circular and table saws, slower movements for jigsaws).

4. Smooth the Edges After cutting, the edges may be rough. Use sandpaper or a file to smooth any rough edges to avoid injury and improve aesthetics.

Safety Considerations

Always prioritize safety when cutting HDPE sheets. Wear protective eyewear and gloves to shield yourself from sharp edges and debris. If using power tools, ensure you follow the manufacturer's instructions and maintain awareness of your surroundings.

Conclusion

Cutting HDPE sheets can be a straightforward process if done with the right tools and safety precautions. Whether you're working on a DIY project, industrial application, or artistic endeavor, understanding the methods and equipment available will help you achieve precise and effective results. By following the described strategies, you'll be well on your way to successfully cutting HDPE sheets to meet your project’s demands.

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025

-

Premium PP Welding Rod: GPT-4 Turbo Enhanced

NewsAug.01,2025

-

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

NewsAug.01,2025

-

Premium PVC Transparent Pipe: Durable & Clear Solutions

NewsJul.31,2025

-

High-Quality UPVC Electrical Pipe for Safe Wiring Solutions

NewsJul.30,2025