Set . 16, 2024 02:37 Back to list

poly pipe fittings

Understanding Poly Pipe Fittings A Comprehensive Overview

Polyethylene (PE) pipe fittings have become increasingly popular in various industries due to their versatility, durability, and ease of installation. These fittings are primarily used in plastic piping systems for transporting fluids, making them an essential component in irrigation, water supply, and industrial applications. In this article, we will explore the characteristics, benefits, and types of poly pipe fittings.

Characteristics of Poly Pipe Fittings

Poly pipe fittings are typically made from high-density polyethylene (HDPE) or medium-density polyethylene (MDPE), which are known for their excellent resistance to corrosion, chemicals, and UV radiation. This makes them ideal for both above-ground and underground installations. The fittings can handle a wide range of temperatures and pressures, making them suitable for various applications, from agricultural to municipal water systems.

One of the key features of poly pipe fittings is their flexibility. Unlike traditional metal fittings, poly fittings can easily bend and adapt to various installation environments without losing structural integrity. This flexibility helps to reduce the risk of leaks and breaks during installation and operation.

Benefits of Using Poly Pipe Fittings

1. Durability Poly pipe fittings resist rust and corrosion, significantly extending the life of the plumbing system. This durability minimizes maintenance requirements and replacement costs over time.

poly pipe fittings

2. Cost-Effectiveness Compared to metal fittings, poly fittings are generally more affordable. Their lightweight nature also reduces shipping costs and makes transport easier for large projects.

3. Ease of Installation Poly pipe fittings can be connected using a variety of methods, including heat fusion, electrofusion, and mechanical fittings. This versatility allows for quick and efficient installation, saving time and labor costs.

4. Environmental Impact Polyethylene is recyclable, making poly pipe fittings a more environmentally friendly option compared to traditional materials. Additionally, the longevity of these fittings leads to less waste generation.

Types of Poly Pipe Fittings

There are several types of poly pipe fittings, each designed for specific applications. Some common types include

- Elbows Used to change the direction of the piping system (e.g., 90-degree or 45-degree angles). - Tees Allow for branching pipes in a system, facilitating connections to other pipes. - Reducers Used to connect pipes of different diameters, ensuring a smooth flow of fluid. - Couplings Joining two straight lengths of pipe, couplings are essential for extending pipe runs.

In conclusion, poly pipe fittings offer a reliable and economical solution for a wide range of applications. Their durability, flexibility, and ease of installation make them an attractive choice for contractors and engineers alike. As demand for efficient and sustainable infrastructure grows, the use of poly pipe fittings will likely continue to rise in various sectors, enhancing both performance and longevity in fluid transport systems.

-

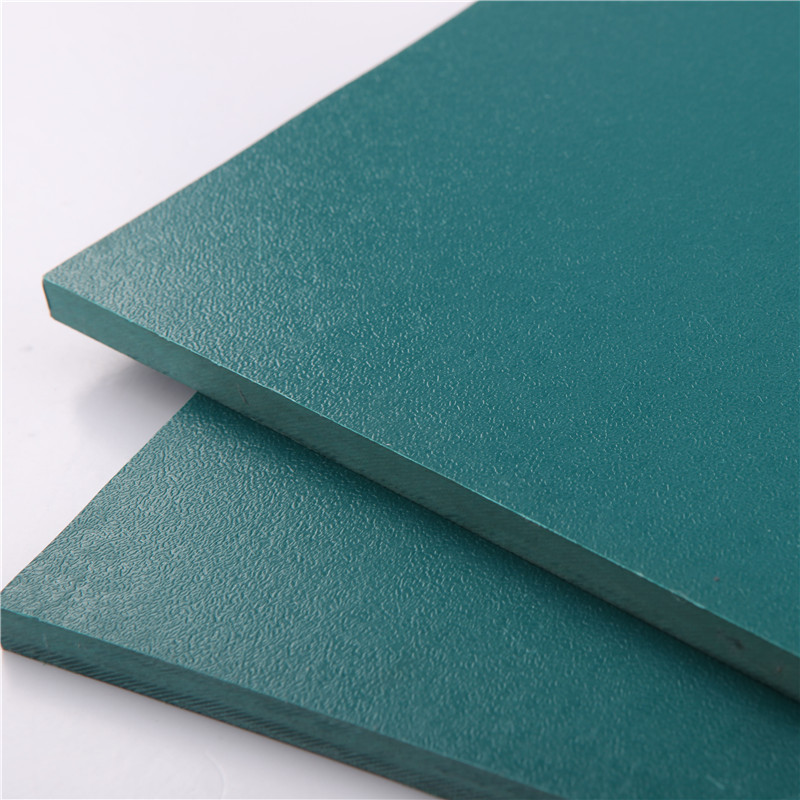

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025