Samh . 16, 2024 06:36 Back to list

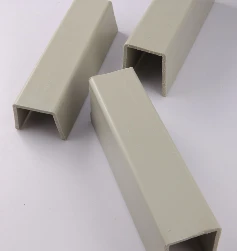

textured hdpe sheet

Exploring Textured HDPE Sheets Versatility and Applications

High-Density Polyethylene (HDPE) is a widely recognized thermoplastic polymer known for its high strength-to-density ratio. One of the most exciting variations of HDPE is the textured HDPE sheet, which brings unique characteristics that expand its applicability across various industries. In this article, we will delve into the properties, benefits, and diverse applications of textured HDPE sheets.

Textured HDPE sheets are manufactured with a defined surface pattern that enhances the material's properties and aesthetic appeal. This texturing process can involve multiple techniques, such as embossing or rolling, which create specific textures such as matte, ribbed, or studded surfaces. These surfaces not only improve the tactile experience but also provide additional functionality, such as increased grip and reduced slip, making them ideal for applications where traction is crucial.

Exploring Textured HDPE Sheets Versatility and Applications

Another considerable benefit is the ease of maintenance. Textured HDPE sheets can be easily cleaned, as their smooth surfaces repel dirt and debris while minimizing the risk of corrosion or mold build-up. This attribute is particularly beneficial in industries like food processing and healthcare, where hygiene is paramount. Regular cleaning ensures that the textured surfaces remain both functional and visually appealing, extending the lifespan of the material.

textured hdpe sheet

In terms of design flexibility, textured HDPE sheets can be produced in various colors and thicknesses, allowing for customization according to specific project requirements. This versatility makes them popular in various sectors, including construction, automotive, aviation, and signage. Architects and designers are particularly fond of using textured HDPE for interior fixtures, wall coverings, and furniture because they offer a modern aesthetic with practical benefits.

One of the notable applications of textured HDPE sheets is in playground equipment. The non-slip surface helps ensure safety for children playing while also being resistant to fading from UV exposure, which prolongs the life of outdoor installations. Furthermore, in marine environments, textured HDPE is used for docks and boardwalks, providing a stable and slip-resistant surface that can withstand harsh weather conditions.

In the healthcare industry, textured HDPE sheets are often utilized for medical equipment, cabinetry, and work surfaces. The material's resistance to chemicals means it can endure various disinfectants without degrading, making it a perfect choice for sterile environments.

Moreover, the eco-friendly nature of HDPE adds another layer of appeal. HDPE can be recycled, and the production of textured sheets often involves methods that minimize environmental impact. Choosing textured HDPE sheets demonstrates a commitment to sustainability while providing high-quality performance.

In conclusion, textured HDPE sheets combine durability, aesthetic appeal, ease of maintenance, and versatility, making them an ideal solution for various applications. Whether in playgrounds, healthcare facilities, or modern architecture, their unique properties provide functional and visual solutions that meet the needs of countless industries. As the demand for innovative and sustainable materials continues to rise, textured HDPE sheets stand out as a leading choice for designers and engineers alike.

-

Transparent PP Sheets High Clarity, Durable & Versatile Solutions

NewsMay.11,2025

-

HDPE Drip Irrigation Pipes Durable, Corrosion-Resistant Solutions

NewsMay.11,2025

-

1.5 Inch PVC Pipe Durable & Corrosion-Resistant Irrigation Solutions

NewsMay.10,2025

-

Durable PP Sheets Polypropylene & Transparent PP Sheet Solutions

NewsMay.10,2025

-

1 Inch HDPE Sheet Durable, Chemical-Resistant Industrial Grade

NewsMay.10,2025

-

China PVC Rigid Sheet Supplier Durable & Custom Thickness Options

NewsMay.10,2025