Gearr . 19, 2025 07:52 Back to list

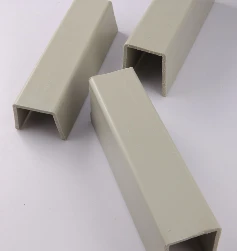

pipe fittings

In the world of plumbing and construction, pipe fittings are of paramount importance. They stand as the unsung heroes of any pipeline system, connecting various pipes and components to form coherent systems that transport liquids and gases seamlessly. To the uninitiated, pipe fittings may seem like mere small-scale components, but their significance cannot be overstated. Let's delve into this vital aspect of construction and plumbing, aimed at giving you a comprehensive understanding of pipe fittings and their role in ensuring streamlined operations and enhanced longevity of piping systems.

Moreover, real-world experience underscores the significance of understanding the specific demands of the project at hand. Experienced professionals know that while the technical specifications of pipe fittings are essential, real-world installation conditions can vary. An expert's intuition about factors such as potential thermal expansion, pressure drops, and maintenance accessibility during fitting selection can make all the difference in the long term performance of a system. Innovation is also shaping the future of pipe fittings, with the advent of smart technologies and sustainable materials. The latest developments include smart fittings equipped with sensors that can monitor and relay system information, hence optimizing maintenance schedules and preemptively identifying potential issues. This technological evolution underscores the importance of staying updated with industry trends and advancements to maintain a competitive edge. In terms of authoritativeness and trustworthiness, the best practitioners in the realm of pipe fittings are those who stand by their work through extensive warranties and after-sale support. Offering responsive customer service and demonstrating accountability fosters trust and long-term relationships with clients, who rely on the expert's judgment and experience. In conclusion, pipe fittings are indispensable to any plumbing or piping system. Their variety, material composition, and the standards they meet all contribute to the efficiency and reliability of a system. Expertise combined with real-world application, continued professional development, and a commitment to quality service delivery guarantees that specialists in the field can provide unmatched value. As the landscape of building and construction evolves, those who adapt and integrate new technologies will lead in setting benchmarks for efficiency, safety, and reliability in pipe fitting solutions.

Moreover, real-world experience underscores the significance of understanding the specific demands of the project at hand. Experienced professionals know that while the technical specifications of pipe fittings are essential, real-world installation conditions can vary. An expert's intuition about factors such as potential thermal expansion, pressure drops, and maintenance accessibility during fitting selection can make all the difference in the long term performance of a system. Innovation is also shaping the future of pipe fittings, with the advent of smart technologies and sustainable materials. The latest developments include smart fittings equipped with sensors that can monitor and relay system information, hence optimizing maintenance schedules and preemptively identifying potential issues. This technological evolution underscores the importance of staying updated with industry trends and advancements to maintain a competitive edge. In terms of authoritativeness and trustworthiness, the best practitioners in the realm of pipe fittings are those who stand by their work through extensive warranties and after-sale support. Offering responsive customer service and demonstrating accountability fosters trust and long-term relationships with clients, who rely on the expert's judgment and experience. In conclusion, pipe fittings are indispensable to any plumbing or piping system. Their variety, material composition, and the standards they meet all contribute to the efficiency and reliability of a system. Expertise combined with real-world application, continued professional development, and a commitment to quality service delivery guarantees that specialists in the field can provide unmatched value. As the landscape of building and construction evolves, those who adapt and integrate new technologies will lead in setting benchmarks for efficiency, safety, and reliability in pipe fitting solutions.

Share:

Next:

Latest news

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025

-

Premium PP Welding Rod: GPT-4 Turbo Enhanced

NewsAug.01,2025

-

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

NewsAug.01,2025

-

Premium PVC Transparent Pipe: Durable & Clear Solutions

NewsJul.31,2025

-

High-Quality UPVC Electrical Pipe for Safe Wiring Solutions

NewsJul.30,2025