Samh . 02, 2024 04:18 Back to list

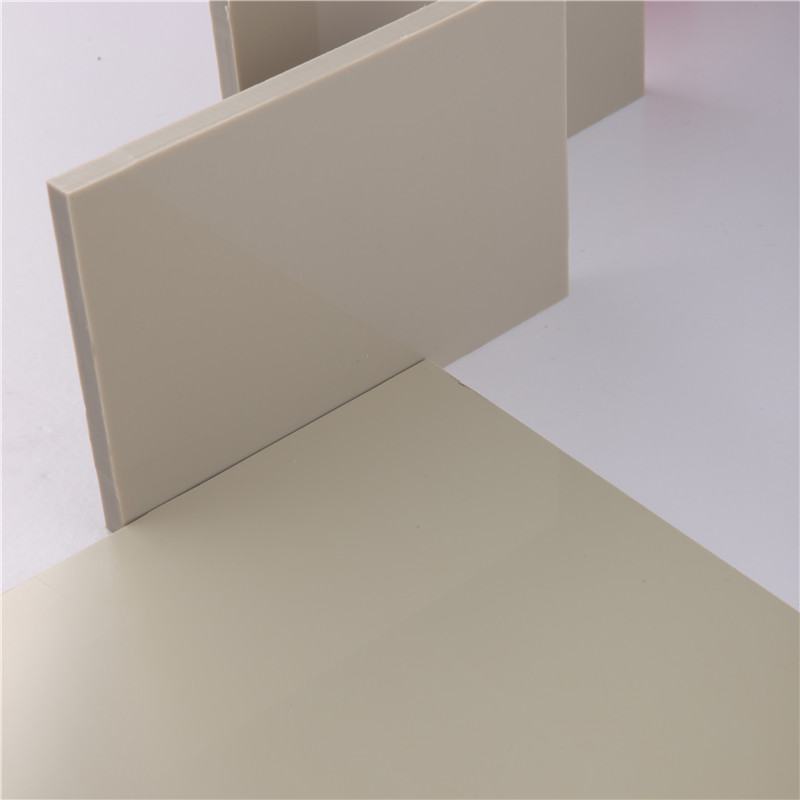

cpvc chemical pipe

Understanding CPVC Chemical Pipes A Comprehensive Overview

Chlorinated Polyvinyl Chloride (CPVC) pipes have become an essential choice in various industries, particularly for conveying chemicals and hot water. Known for their resilience and versatility, CPVC pipes provide a robust solution for environments that involve corrosive chemicals, high temperatures, and demanding pressure conditions.

What is CPVC?

CPVC is a thermoplastic produced by the chlorination of polyvinyl chloride (PVC). This chemical modification enhances the material’s thermal stability and chemical resistance. CPVC pipes are notably suitable for transporting a range of chemicals used in industrial processes, including acids, bases, and solvents. Because of these properties, they are widely used in chemical processing plants, water treatment facilities, and residential plumbing systems.

Advantages of CPVC Pipes

1. Chemical Resistance One of the primary benefits of CPVC pipes is their exceptional resistance to a wide array of chemicals. This property allows them to withstand the harsh conditions often found in chemical processing and handling.

2. Temperature Tolerance CPVC can handle temperatures exceeding 200°F (93°C), making it an excellent choice for hot water distribution systems. This characteristic ensures that CPVC remains functional and reliable, even under high thermal stress.

cpvc chemical pipe

3. Durability CPVC pipes are highly resistant to corrosion, scaling, and pitting. This durability translates into extended service life, reducing the need for frequent replacements and maintenance.

4. Ease of Installation The lightweight nature of CPVC pipes makes them easier to handle and transport compared to metallic alternatives. Their installation is straightforward, often utilizing solvent cement, which results in a strong and leak-proof joint.

5. Cost-Effectiveness Compared to other materials, CPVC pipes are often more affordable, both in terms of initial material costs and long-term durability. Their low maintenance requirements further enhance their cost-effectiveness.

Applications of CPVC Pipes

CPVC pipes find use in various applications across multiple industries. In the chemical industry, they are commonly employed for fluid transfer in processing plants, facilitating the movement of acids, alkalis, and other corrosive substances. Additionally, the plumbing and heating sectors utilize CPVC due to its high-temperature resistance, particularly in conducting hot water in residential and commercial buildings.

Conclusion

In summary, CPVC chemical pipes offer a plethora of advantages, including exceptional chemical resistance, high-temperature tolerance, durability, ease of installation, and cost-effectiveness. These features make them a crucial component in modern industrial applications and plumbing systems. As industries continue to evolve and demand reliable and efficient materials, CPVC pipes are poised to remain a leading choice for those looking to ensure safety, reliability, and performance in their chemical conveyance systems. Whether in a chemical plant or a residential setting, the benefits of CPVC pipes cannot be overstated, solidifying their indispensable role in today’s infrastructure.

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025