Nov . 21, 2024 14:01 Back to list

industrial pipe fittings

Understanding Industrial Pipe Fittings A Comprehensive Overview

Industrial pipe fittings play a crucial role in various applications, ranging from plumbing and HVAC systems to oil and gas industries. These fittings are essential components that connect pipes, allowing for the smooth flow of liquids and gases. Given their widespread use and critical importance, a deeper understanding of industrial pipe fittings is vital for professionals in engineering, construction, and maintenance.

Pipe fittings come in a wide variety of shapes, sizes, and materials, each designed for specific functions. Common types of fittings include elbows, tees, reducers, couplings, flanges, and caps. Elbows allow for changes in pipe direction, typically at angles of 90 or 45 degrees, while tees enable branching off a main line. Reducers facilitate the connection of pipes with different diameters, ensuring a secure and leak-proof junction. Couplings connect two sections of pipe, and flanges allow for a secure and easily-removable joint between pipes and other equipment.

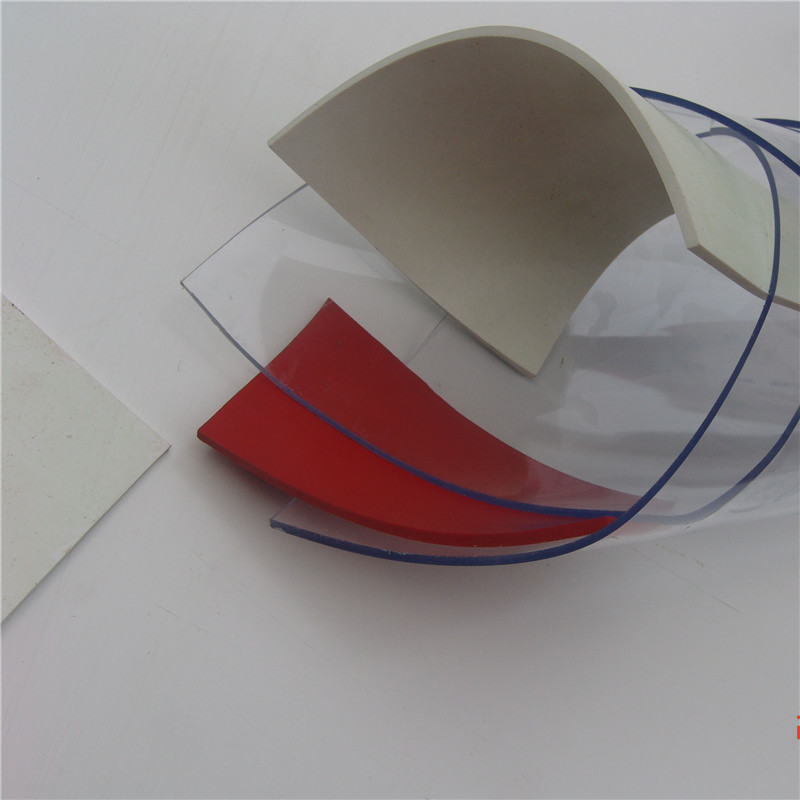

The materials used in the production of pipe fittings vary significantly. Common materials include stainless steel, carbon steel, PVC, copper, and brass. The choice of material often depends on factors such as the type of fluid being transported, temperature, pressure, and the potential for corrosion. For instance, stainless steel is preferred in environments where corrosion is a concern, while PVC is commonly utilized in drainage and non-pressure applications due to its lightweight nature and resistance to chemical corrosion.

industrial pipe fittings

Quality is of paramount importance when it comes to industrial pipe fittings. Substandard fittings can lead to leaks, system failures, and catastrophic accidents. Therefore, it is essential to source fittings from reputable manufacturers who adhere to industry standards and regulations. Additionally, regular inspection and maintenance of pipe fittings are necessary to ensure their integrity and longevity.

Installation of pipe fittings should be performed with precision to minimize the risk of leaks. This involves thorough planning and consideration of the piping layout, as well as using the appropriate tools and techniques during installation. Proper torque specifications on threaded fittings and ensuring that seals and gaskets are correctly placed can significantly reduce the likelihood of complications down the line.

In conclusion, industrial pipe fittings are indispensable elements of modern infrastructure. Their diverse types and materials cater to various applications, making it essential for industry professionals to have a solid understanding of their functions and proper handling. Whether in construction, maintenance, or system design, reliable pipe fittings contribute to the efficiency and safety of industrial operations. As industries continue to evolve, so too will the innovations in pipe fitting technologies, paving the way for improved performance and durability in fluid and gas transportation.

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025

-

Durable PPR Pipe for Hot & Cold Water Systems - Easy Install

NewsAug.14,2025