Mar . 06, 2025 12:23 Back to list

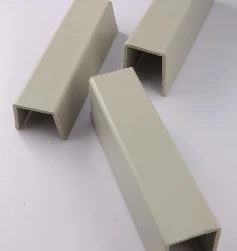

hdpe pipe fitting

The industrial landscape is ever-evolving, with new materials constantly being developed to meet the demands of diverse applications. One such material that has revolutionized the piping industry is High-Density Polyethylene (HDPE). Known for its exceptional properties, HDPE pipe fittings have become a popular choice among professionals seeking reliable, durable, and efficient solutions.

From an expert standpoint, understanding the characteristics of HDPE is vital in selecting the right fittings for specific applications. Its thermal resistance allows it to perform admirably in both extreme cold and heat, a property that ensures functionality across different geographic regions. Furthermore, HDPE is resistant to biological growth, which is essential for maintaining the hygiene and safety of piping systems, especially in potable water applications. The authority of HDPE as a primary material in pipe fittings can be observed in various standards and certifications it meets. Organizations like the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) provide guidelines that HDPE products consistently comply with. This compliance not only assures quality but also enhances the credibility of projects that utilize these components. Trustworthiness in construction materials is non-negotiable, and HDPE has built a reputation for reliability. Many case studies document its successful implementation in high-stake environments, standing the test of time and conditions that would typically challenge traditional materials. Engineers and project managers show a preference for HDPE when seeking proven solutions, evidenced by its widespread use in infrastructure projects worldwide. In conclusion, HDPE pipe fittings represent a synthesis of innovation, efficiency, and sustainability. Their adoption signifies a shift towards modern, resilient infrastructure capable of meeting current and future demands. By leveraging the distinct advantages of HDPE, industries can achieve operational excellence while contributing positively to environmental conservation efforts. As knowledge and expertise around these components continue to grow, so does their potential to redefine standards in piping technology.

From an expert standpoint, understanding the characteristics of HDPE is vital in selecting the right fittings for specific applications. Its thermal resistance allows it to perform admirably in both extreme cold and heat, a property that ensures functionality across different geographic regions. Furthermore, HDPE is resistant to biological growth, which is essential for maintaining the hygiene and safety of piping systems, especially in potable water applications. The authority of HDPE as a primary material in pipe fittings can be observed in various standards and certifications it meets. Organizations like the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) provide guidelines that HDPE products consistently comply with. This compliance not only assures quality but also enhances the credibility of projects that utilize these components. Trustworthiness in construction materials is non-negotiable, and HDPE has built a reputation for reliability. Many case studies document its successful implementation in high-stake environments, standing the test of time and conditions that would typically challenge traditional materials. Engineers and project managers show a preference for HDPE when seeking proven solutions, evidenced by its widespread use in infrastructure projects worldwide. In conclusion, HDPE pipe fittings represent a synthesis of innovation, efficiency, and sustainability. Their adoption signifies a shift towards modern, resilient infrastructure capable of meeting current and future demands. By leveraging the distinct advantages of HDPE, industries can achieve operational excellence while contributing positively to environmental conservation efforts. As knowledge and expertise around these components continue to grow, so does their potential to redefine standards in piping technology.

Share:

Next:

Latest news

-

Premium PP Welding Rod: GPT-4 Turbo Enhanced

NewsAug.01,2025

-

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

NewsAug.01,2025

-

Premium PVC Transparent Pipe: Durable & Clear Solutions

NewsJul.31,2025

-

High-Quality UPVC Electrical Pipe for Safe Wiring Solutions

NewsJul.30,2025

-

Premium PVC Pipe Fitting Supplier – Durable & Leak-Proof Solutions

NewsJul.30,2025

-

High-Gloss PVC Rigid Sheet for Durable & Smooth Surfaces | Wholesale Supply

NewsJul.29,2025