Ira . 28, 2024 12:51 Back to list

Choosing the Right Round PP Welding Rod for Your Projects and Applications

Understanding Round PP Welding Rods A Comprehensive Overview

Welding is an essential process in various manufacturing and construction industries, and the choice of materials plays a significant role in determining the quality and efficiency of welded structures. Among the many options available, round polypropylene (PP) welding rods have gained popularity due to their unique properties and advantages. This article explores the characteristics, applications, and benefits of round PP welding rods, providing valuable insights for professionals in the field.

What are Round PP Welding Rods?

Round PP welding rods are cylindrical pieces made from polypropylene, a thermoplastic polymer known for its versatility, low density, and excellent chemical resistance. These rods are used as filler materials during the welding process, helping to bond two surfaces of polypropylene or related plastics together. The round shape of these rods allows for easy manipulation and effective deposition during welding applications.

Properties of Polypropylene

Polypropylene possesses several properties that make it suitable for various industrial applications

1. Chemical Resistance Polypropylene is resistant to a wide range of chemicals, including acids, alkalis, and organic solvents. This property makes it ideal for use in environments where chemical exposure is likely.

2. Lightweight Being one of the lightest plastics, polypropylene reduces shipping costs and eases handling and installation processes.

3. Durability PP is known for its resilience, making it resistant to impact and stress. This durability contributes to the longevity of welded joints.

4. Temperature Tolerance While PP does have limitations in high-temperature applications, it performs well within a certain range, making it suitable for various industrial processes.

5. Environmentally Friendly Polypropylene can be recycled, contributing to sustainability efforts in manufacturing.

Applications of Round PP Welding Rods

Round PP welding rods are widely used in various sectors due to their impressive properties and versatility. Some common applications include

round pp welding rod

2. Automotive Industry PP welding rods are used in manufacturing components such as bumper covers and interior parts due to their lightweight nature and impact resistance.

3. Medical Equipment In the healthcare sector, polypropylene is often chosen for its biocompatibility, making it suitable for sterilizable medical devices.

4. Construction These rods can be used in building applications, including waterproofing membranes and insulation, benefiting from their chemical resistance and durability.

Benefits of Using Round PP Welding Rods

The use of round PP welding rods comes with several advantages

1. Ease of Use The round shape allows for efficient feeding into welding equipment and enables smoother application during welding processes.

2. Strong Welds When properly applied, round PP welding rods create strong and reliable joints that enhance the integrity of the overall structure.

3. Cost-Effectiveness The relatively low cost of polypropylene combined with its durability and performance makes it an economical choice for many projects.

4. Versatility Round PP welding rods can be used with various welding techniques, including hot air welding, extrusion welding, and friction welding, making them adaptable to different project requirements.

5. Minimal Shrinkage Polypropylene typically has low shrinkage rates during cooling, which helps to maintain the integrity of the welded joint.

Conclusion

Round PP welding rods are an invaluable resource in modern welding applications. Their unique properties, coupled with versatility across different industries, make them a preferred choice for manufacturers and builders alike. Understanding the advantages and applications of these rods can lead to better material selection and enhanced project outcomes, ensuring high-quality welded joints that stand the test of time. As industries continue to evolve, the role of round PP welding rods is likely to grow, making them an essential component of the welding and fabrication landscape.

-

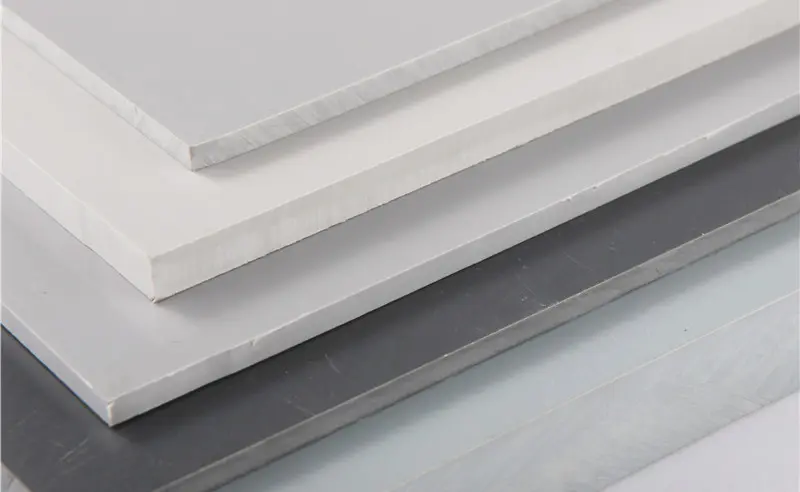

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025