Νοέ . 07, 2024 23:31 Back to list

Understanding PE Pipe Fittings and Their Applications in Modern Plumbing Systems

Understanding PE Pipe Fittings A Comprehensive Overview

Polyethylene (PE) pipe fittings are an essential component in various piping systems, renowned for their durability, versatility, and resistance to corrosion. As industries seek efficient and sustainable methods of transporting fluids, the demand for PE pipe fittings has significantly increased. In this article, we'll explore PE pipe fittings, their types, benefits, applications, and installation considerations.

What are PE Pipe Fittings?

PE pipe fittings are specialized connectors used to join sections of polyethylene pipes. These fittings can assume a variety of shapes and sizes, depending on their intended use. Common types include elbows, tees, reducers, and caps. Each fitting serves a unique function in ensuring the efficient flow of fluids while maintaining the integrity of the piping system.

Types of PE Pipe Fittings

1. Elbows These fittings change the direction of piping, allowing for turns in the layout without needing multiple straight sections. Common angles include 45 and 90 degrees.

2. Tees These fittings allow for branching off, enabling connections with three sections of pipe. They can be used for creating manifold systems or connecting to various delivery points.

3. Reducers Used to connect pipes of different diameters, reducers facilitate the transition from a larger pipe to a smaller one, ensuring a smooth flow and minimizing pressure loss.

4. Caps These fittings are used to close the end of a pipeline, preventing leaks and contamination in the system.

5. Couplings Couplings connect two sections of pipe together, providing a secure and leak-proof joint.

Benefits of PE Pipe Fittings

PE pipe fittings offer numerous advantages, contributing to their growing popularity in various applications

1. Corrosion Resistance Unlike traditional materials like metal, PE is highly resistant to corrosion, making it suitable for use in harsh environments and prolonging the lifespan of the piping system.

2. Lightweight and Durable PE materials are lightweight, making transportation and installation easier. Despite their weight, they are remarkably durable, providing reliable performance even under heavy stress.

3. Flexibility PE pipes and fittings can bend to fit a variety of layouts, reducing the need for numerous fittings and minimizing potential leak points.

4. Smooth Internal Surface The smooth internal surface of PE pipes reduces friction, leading to lower energy consumption and greater efficiency in fluid transport.

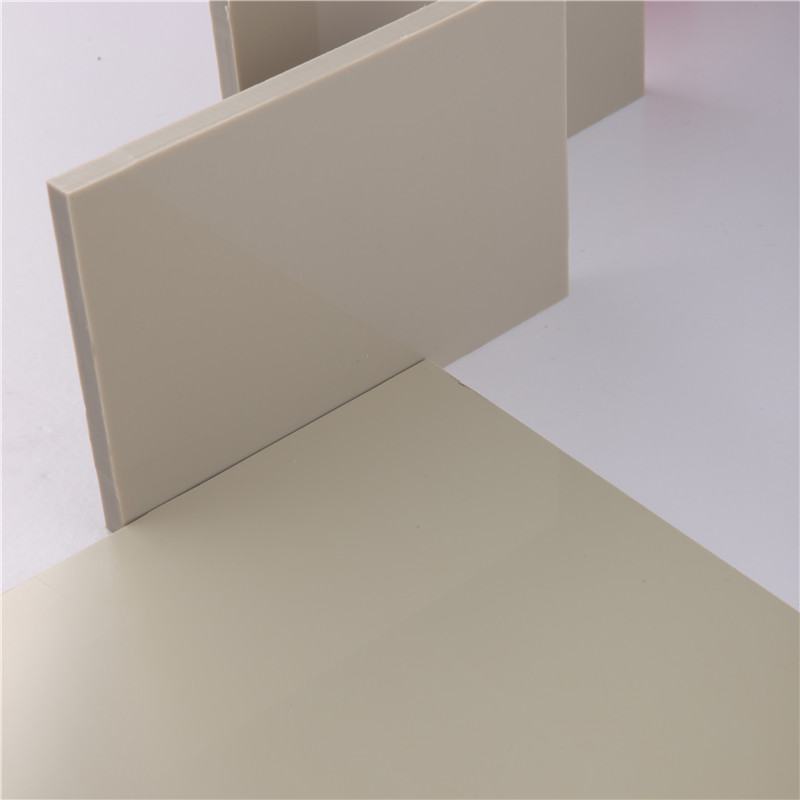

pe pipe fittings

Applications of PE Pipe Fittings

PE pipe fittings are utilized across a myriad of industries and applications

- Water Supply Systems They play a crucial role in municipal water supply systems, ensuring safe and efficient water distribution.

- Agricultural Irrigation PE fittings are commonly used in irrigation systems, providing farmers with reliable pathways for transporting water to crops.

- Sewage and Drainage They are essential for effective sewage systems, providing leak-proof connections that prevent contamination of surrounding soil and groundwater.

- Gas Distribution In many regions, PE fittings are utilized for safe gas distribution, ensuring longevity and safety in pipelines.

Installation Considerations

Proper installation of PE pipe fittings is vital to ensure reliability. Key considerations include

- Alignment and Support Ensuring that the pipes and fittings are aligned correctly is crucial for preventing stress and potential leaks. Adequate support must be provided to prevent sagging.

- Cleaning the Surface Before installation, the surfaces of the pipes and fittings should be cleaned to remove any dirt or debris, facilitating a tight seal.

- Proper Tools Utilize suitable tools designed for PE fittings to avoid damaging the materials during installation.

- Follow Manufacturer Guidelines Adhering to the installation guidelines provided by manufacturers can prevent issues down the line.

Conclusion

PE pipe fittings represent an innovative solution for modern plumbing and piping needs, contributing to the efficiency and sustainability of fluid transport systems. With their myriad benefits and diverse applications, understanding these fittings is paramount for professionals in construction, agriculture, and municipal services. As industries continue to evolve, the importance of PE pipe fittings in promoting environmental sustainability is likely to grow, securing their place as a key component in the future of piping solutions.

-

Durable PP Rigid Sheet: Versatile & High-Quality Plastic Panels

NewsAug.08,2025

-

Premium Glossy PP Rigid Sheet – Durable & Versatile

NewsAug.07,2025

-

High-Quality HDPE Sheet | Durable Plastic Panels

NewsAug.06,2025

-

High-Precision PVC Rigid Sheets for Vacuum Forming | AI-Optimized

NewsAug.05,2025

-

Durable PVC-M Water Supply Pipes | 60-Year Life

NewsAug.04,2025

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025