Rhag . 15, 2024 10:25 Back to list

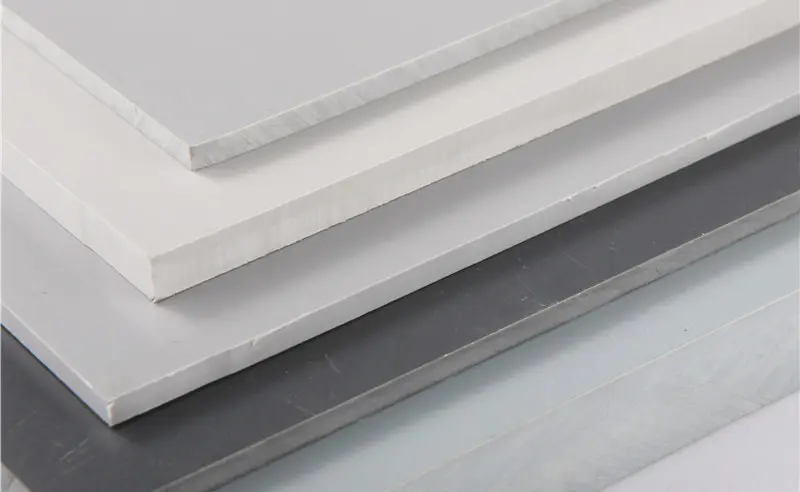

hdpe sheet thickness

Understanding HDPE Sheet Thickness A Comprehensive Guide

High-Density Polyethylene (HDPE) is a versatile thermoplastic polymer that has gained immense popularity due to its strength, durability, and resistance to various environmental factors. One of the critical aspects of HDPE materials is their thickness, which plays a significant role in determining their suitability for various applications. This article delves into the importance of HDPE sheet thickness, its measurement, and the implications for different uses.

HDPE sheets come in a range of thicknesses, typically ranging from 0.5 mm (0.02 inches) to several inches thick, depending on the application requirements. The thickness of an HDPE sheet impacts its mechanical properties, including tensile strength, impact resistance, and rigidity. Thicker sheets generally offer greater strength and durability, making them ideal for load-bearing applications. Conversely, thinner sheets are more flexible and easier to work with, which can be advantageous in applications requiring bending or shaping.

Understanding HDPE Sheet Thickness A Comprehensive Guide

Applications of HDPE sheets vary widely, from industrial uses to consumer products. In construction, for example, HDPE sheets are used for liners in landfills and ponds due to their excellent impermeability and resistance to chemicals. The thickness of the HDPE sheet is crucial in these situations, as it must withstand not only environmental stressors but also the weight of materials placed upon it.

hdpe sheet thickness

In the agricultural sector, HDPE sheets serve as weed barriers and surface covers. Thicker sheets are often preferred in these applications to ensure longevity and minimize the risk of tearing or puncturing, which could compromise their effectiveness. On the other hand, in the construction of signage and displays, thinner HDPE sheets may be more suitable as they are lightweight and easier to handle.

Another vital aspect of HDPE sheet thickness is its role in thermal properties. Thicker sheets offer better insulation, which can be beneficial in applications involving temperature fluctuations. For instance, in the food packaging industry, maintaining product integrity is essential, and the right thickness can assist in optimizing insulation and protection.

When selecting HDPE sheet thickness, it is also essential to consider factors such as weight, ease of fabrication, and cost. While thicker sheets provide greater durability, they may also increase shipping costs due to their weight. Additionally, they may require specialized tools for cutting and shaping, which could impact project timelines and overall costs.

In conclusion, understanding HDPE sheet thickness is paramount for selecting the right material for your specific needs. With its varied applications across multiple industries, the choice of thickness influences not only performance and longevity but also fabrication and cost considerations. Whether you are working on an industrial project, agricultural application, or consumer product, it is crucial to assess the required thickness carefully. Consulting with industry professionals and suppliers can provide valuable insights and help ensure that you select the right HDPE sheet thickness to meet your project specifications effectively. By taking the time to understand these factors, you can optimize your use of HDPE sheets, ensuring durability and efficiency in your applications.

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025