Jan . 09, 2025 10:37 Back to list

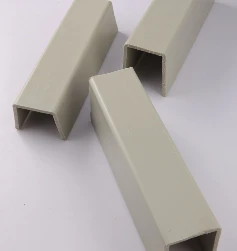

PP rigid sheet(glossy surface)

Polypropylene sheets, commonly known as PP sheets, have carved a niche in the realm of versatile and sustainable materials catering to a multitude of industries. From packaging to automotive, these sheets offer a plethora of applications driven by their unique properties.

The authoritativeness of PP sheets is cemented by their widespread acceptance and certification across numerous industries. Compliance with FDA regulations for food safety and the ability to be fully recycled support their authoritative standing as a safe and sustainable choice. This is particularly crucial in the packaging industry where the demand for eco-friendly materials is ever-increasing. Companies leveraging PP sheets in their packaging solutions frequently cite the added benefit of meeting stringent environmental regulatory requirements. Trustworthiness among users and businesses is often derived from the consistent quality and performance of PP sheets over time. Testimonials from various sectors such as construction, agriculture, and healthcare corroborate the reliability of these sheets. For instance, in construction, PP sheets are utilized for moisture barriers because they exhibit reliable water resistance. Healthcare professionals also rely on PP sheets for non-toxic and sterility-preserving properties in medical packaging solutions. In conclusion, PP sheets stand out not only due to their technical attributes but also because of the breadth of industry knowledge and practical experiences that validate their application. By continuing to innovate and adapt polypropylene sheets for new uses, industries can both reduce their carbon footprint and enhance the efficiency of their operations. This makes PP sheets a compelling choice for businesses looking to drive sustainability and innovation simultaneously, further solidifying their position as a leader in modern material solutions.

The authoritativeness of PP sheets is cemented by their widespread acceptance and certification across numerous industries. Compliance with FDA regulations for food safety and the ability to be fully recycled support their authoritative standing as a safe and sustainable choice. This is particularly crucial in the packaging industry where the demand for eco-friendly materials is ever-increasing. Companies leveraging PP sheets in their packaging solutions frequently cite the added benefit of meeting stringent environmental regulatory requirements. Trustworthiness among users and businesses is often derived from the consistent quality and performance of PP sheets over time. Testimonials from various sectors such as construction, agriculture, and healthcare corroborate the reliability of these sheets. For instance, in construction, PP sheets are utilized for moisture barriers because they exhibit reliable water resistance. Healthcare professionals also rely on PP sheets for non-toxic and sterility-preserving properties in medical packaging solutions. In conclusion, PP sheets stand out not only due to their technical attributes but also because of the breadth of industry knowledge and practical experiences that validate their application. By continuing to innovate and adapt polypropylene sheets for new uses, industries can both reduce their carbon footprint and enhance the efficiency of their operations. This makes PP sheets a compelling choice for businesses looking to drive sustainability and innovation simultaneously, further solidifying their position as a leader in modern material solutions.

Share:

Next:

Latest news

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025

-

Durable PPR Pipe for Hot & Cold Water Systems - Easy Install

NewsAug.14,2025

-

Durable HDPE Sheet | Versatile & Impact-Resistant Plastic

NewsAug.13,2025