Okt . 14, 2024 11:04 Back to list

HDPE Coil Pipe Applications and Benefits in Modern Infrastructure Systems

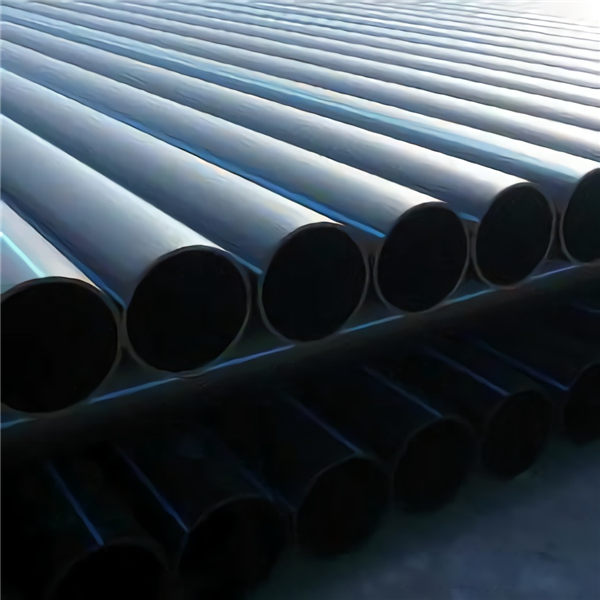

The Versatility and Applications of HDPE Coil Pipe

High-Density Polyethylene (HDPE) coil pipe has emerged as a transformative solution in various industries due to its remarkable properties and benefits. This flexible piping system is made from high-density polyethylene, a thermoplastic material known for its durability, chemical resistance, and low maintenance requirements. As industries continue to seek efficient and sustainable methods for transporting liquids and gases, HDPE coil pipe stands out for several compelling reasons.

1. Characteristics of HDPE Coil Pipe

HDPE coil pipes are crafted through an extrusion process, resulting in long, continuous lengths without joints, making them ideal for various applications. Their flexibility allows them to curve around obstacles and fit into tight spaces, which other piping solutions cannot simply accommodate. Additionally, HDPE is resistant to corrosion, meaning the pipe won't rust or degrade when exposed to a range of chemicals.

One of the standout features of HDPE coil pipe is its lightweight nature, which makes it easy to handle and install. This attribute translates into reduced transportation costs and quicker installation times. Furthermore, HDPE coil pipes exhibit a smooth interior surface, minimizing friction and thereby improving flow efficiency.

2

. Environmental BenefitsIn an age increasingly concerned with environmental sustainability, HDPE coil pipes present a compelling choice. They are manufactured from recycled materials and are themselves recyclable, reducing their carbon footprint. The longevity of HDPE pipes—often lasting over 50 years—along with their resistance to UV radiation, means fewer replacements are needed over time.

Because they do not rust or corrode, they do not leach harmful substances into the soil or water, making them an environmentally friendly option for water and wastewater applications. Their energy-efficient production process and low thermal conductivity also contribute to a lower environmental impact.

3. Applications of HDPE Coil Pipe

hdpe coil pipe

The versatility of HDPE coil pipe allows its usage across various sectors. In agriculture, these pipes are commonly used for irrigation systems, enabling efficient water distribution while minimizing evaporation and runoff. The flexible nature of HDPE makes it suitable for complex irrigation designs that can accommodate the contours of the land.

In municipal applications, HDPE coil pipes are used for water supply, sewer systems, and stormwater management. Their ability to withstand high pressures and resistance to chemicals ensures reliability and effectiveness in transporting drinking water and handling wastewater.

In industrial contexts, HDPE pipes are utilized in chemical processing due to their resistance to corrosive substances. They are also increasingly being used for gas distribution, as their durability ensures safety and longevity.

4. Installation and Maintenance

The installation of HDPE coil pipe is often simpler and less labor-intensive compared to traditional piping systems. Because they can be installed in long runs with fewer joints, the chances of leaks decrease significantly. Fusion welding is the most common method used to connect HDPE pipes, creating a seamless and leak-proof joint that enhances the overall reliability of the system.

Maintenance is minimal due to the pipe's resistance to both corrosion and scale buildup. This durability translates into lower operational costs over time, making HDPE coil pipes a financially savvy choice for many businesses.

5. Conclusion

In summary, HDPE coil pipe represents a modern solution to various piping needs across multiple industries. Its combination of flexibility, durability, and environmental benefits positions it as a highly effective alternative to traditional piping materials. As industries continue to evolve and embrace sustainable practices, the demand for reliable and efficient systems like HDPE coil pipe is likely to grow. Investing in these piping solutions not only meets current operational needs but also fosters a more sustainable future for generations to come. Whether used in agriculture, municipal applications, or industrial settings, HDPE coil pipe demonstrates the potential to transform how we think about fluid and gas transportation, underscoring the importance of innovation in material science.

-

High Transparency PVC Clear Sheet Super Transparency PVC Sheets & HDPE Cutting Board Supplier

NewsJul.04,2025

-

High-Quality PVC-M Pipe Supplier Trusted PVC Pipe Company & 75mm PVC Connection Pipe Solutions

NewsJul.04,2025

-

PVC Transparent Sheet Roll - Durable & Flexible PVC Plastic Sheet Roll for Industrial & Home Use

NewsJun.24,2025

-

High-Quality PVC PPR Pipes and Fittings Durable ERA PPR Solutions

NewsJun.10,2025

-

High-Quality Large HDPE Sheets & Large Diameter PVC Pipe Durable Large PVC Pipe Supplier

NewsJun.10,2025

-

High Density Polyethylene Cutting Board - Durable & Food Safe

NewsJun.09,2025