jan . 29, 2025 05:45 Back to list

HDPE Natural Sheet

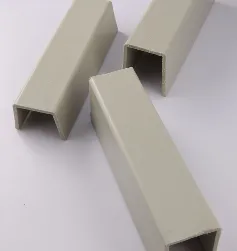

Polypropylene (PP) welding rods have revolutionized the art of plastic welding, offering unmatched versatility and reliability in joining polypropylene materials. With a deep dive into the technical and practical aspects of PP welding rods, one gains not only expertise but also the trust to make informed, authoritative decisions in the field of polymer applications.

Authoritative use of PP welding rods requires a thorough understanding of the preparation phase. Surfaces must be clean and free from contaminants to achieve a perfect weld. This includes removing any oil, dust, or paint present on the surfaces to be joined. Using specialized alcohol-based cleaning agents and abrasion methods can significantly improve the welding outcomes. Experience shows that practicing proper technique can also mitigate common issues such as warpage or misalignment during the welding process. Stabilizing the workpieces to avoid movement during welding, and employing the right pressure ensures the formation of a seamless joint. Moreover, employing test welds can gauge the settings and the approach needed, adding confidence to the subsequent processes with more critical parts. Trustworthiness in PP welding rod applications is reinforced through understanding the safety and environmental considerations involved. PP materials are thermoplastic, meaning they can release fumes when heated. Using protective equipment such as masks and ensuring well-ventilated workspaces protects against inhalation of potentially harmful emissions. Furthermore, proper disposal of plastic waste aligns with environmental standards and promotes sustainable practices. In conclusion, mastery over polypropylene welding rods is not merely a matter of understanding the technical specifications but also of applying them with a level of expertise that ensures quality outcomes. By integrating knowledge, precise technique, and a commitment to safety and sustainability, these rods become a reliable tool for creating robust and long-lasting polymer joints. For the industries relying on PP components, the assurance of quality welding processes transforms into operational efficiency and product longevity, setting a high standard in the field of plastic welding.

Authoritative use of PP welding rods requires a thorough understanding of the preparation phase. Surfaces must be clean and free from contaminants to achieve a perfect weld. This includes removing any oil, dust, or paint present on the surfaces to be joined. Using specialized alcohol-based cleaning agents and abrasion methods can significantly improve the welding outcomes. Experience shows that practicing proper technique can also mitigate common issues such as warpage or misalignment during the welding process. Stabilizing the workpieces to avoid movement during welding, and employing the right pressure ensures the formation of a seamless joint. Moreover, employing test welds can gauge the settings and the approach needed, adding confidence to the subsequent processes with more critical parts. Trustworthiness in PP welding rod applications is reinforced through understanding the safety and environmental considerations involved. PP materials are thermoplastic, meaning they can release fumes when heated. Using protective equipment such as masks and ensuring well-ventilated workspaces protects against inhalation of potentially harmful emissions. Furthermore, proper disposal of plastic waste aligns with environmental standards and promotes sustainable practices. In conclusion, mastery over polypropylene welding rods is not merely a matter of understanding the technical specifications but also of applying them with a level of expertise that ensures quality outcomes. By integrating knowledge, precise technique, and a commitment to safety and sustainability, these rods become a reliable tool for creating robust and long-lasting polymer joints. For the industries relying on PP components, the assurance of quality welding processes transforms into operational efficiency and product longevity, setting a high standard in the field of plastic welding.

Share:

Next:

Latest news

-

Durable PVC-M Water Supply Pipes | 60-Year Life

NewsAug.04,2025

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025

-

Premium PP Welding Rod: GPT-4 Turbo Enhanced

NewsAug.01,2025

-

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

NewsAug.01,2025

-

Premium PVC Transparent Pipe: Durable & Clear Solutions

NewsJul.31,2025