feb . 06, 2025 01:14 Back to list

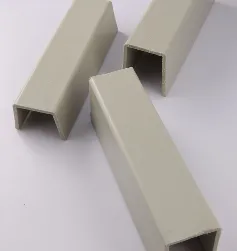

hdpe sheet sizes

High-density polyethylene (HDPE) sheets are transforming how industries approach material choices due to their exceptional properties and versatility. As a recognized authority in material selection, leveraging HDPE sheets can significantly optimize both performance and costs across various applications.

From an expertise perspective, HDPE sheets' chemical resistance cannot be overlooked, especially in agricultural or chemical processing settings. Their inert nature means they resist reactions with most common chemicals and fertilizing agents. This feature enhances safety and reliability, reducing risk management concerns about chemical exposures or material failures. Such confidence in a product only comes from years of trusted application and extensive use-case validations. HDPE sheets also deliver profound insulating properties, harnessed in industries where temperature control is critical. Their low thermal conductivity protects against extreme temperatures, making them an excellent choice for thermal barriers or insulative liners in construction. This professional insight aligns with energy conservation goals and sustainable practices becoming paramount in modern projects. Another testament to the sheets' authoritativeness lies in their sustainable benefits. HDPE sheets are recyclable, aligning with global environmental standards and compliance statues. In industries moving towards greener solutions, utilizing a material that can be repurposed post-use adds not only value but also credibility to a company’s sustainability initiatives. Experts focusing on environmental impacts highly recommend integrating HDPE into production processes for its life cycle benefits. Finally, trust is solidified through the legacy of HDPE applications providing consistent results across decades. Users familiar with their durability and robustness often advocate for HDPE sheets as the go-to material when reliability cannot be compromised. This trust is backed by certifications and material testing standards from recognized organizations, ensuring each batch meets stringent industry requirements. For enterprises considering material upgrades, HDPE sheets present a comprehensive solution blending durability, versatility, and responsible stewardship. Choosing HDPE not only equips your projects with a proven material but opens opportunities for innovation in applications previously deemed challenging. As a product, HDPE continues to earn its position as a cornerstone in material engineering and industrial solutions, thanks to its unparalleled performance and the steadfast confidence it inspires among industry leaders and experts.

From an expertise perspective, HDPE sheets' chemical resistance cannot be overlooked, especially in agricultural or chemical processing settings. Their inert nature means they resist reactions with most common chemicals and fertilizing agents. This feature enhances safety and reliability, reducing risk management concerns about chemical exposures or material failures. Such confidence in a product only comes from years of trusted application and extensive use-case validations. HDPE sheets also deliver profound insulating properties, harnessed in industries where temperature control is critical. Their low thermal conductivity protects against extreme temperatures, making them an excellent choice for thermal barriers or insulative liners in construction. This professional insight aligns with energy conservation goals and sustainable practices becoming paramount in modern projects. Another testament to the sheets' authoritativeness lies in their sustainable benefits. HDPE sheets are recyclable, aligning with global environmental standards and compliance statues. In industries moving towards greener solutions, utilizing a material that can be repurposed post-use adds not only value but also credibility to a company’s sustainability initiatives. Experts focusing on environmental impacts highly recommend integrating HDPE into production processes for its life cycle benefits. Finally, trust is solidified through the legacy of HDPE applications providing consistent results across decades. Users familiar with their durability and robustness often advocate for HDPE sheets as the go-to material when reliability cannot be compromised. This trust is backed by certifications and material testing standards from recognized organizations, ensuring each batch meets stringent industry requirements. For enterprises considering material upgrades, HDPE sheets present a comprehensive solution blending durability, versatility, and responsible stewardship. Choosing HDPE not only equips your projects with a proven material but opens opportunities for innovation in applications previously deemed challenging. As a product, HDPE continues to earn its position as a cornerstone in material engineering and industrial solutions, thanks to its unparalleled performance and the steadfast confidence it inspires among industry leaders and experts.

Share:

Next:

Latest news

-

High-Quality HDPE Sheet | Durable Plastic Panels

NewsAug.06,2025

-

High-Precision PVC Rigid Sheets for Vacuum Forming | AI-Optimized

NewsAug.05,2025

-

Durable PVC-M Water Supply Pipes | 60-Year Life

NewsAug.04,2025

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025

-

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

NewsAug.01,2025