Ліст . 05, 2024 05:04 Back to list

welding rods for pvc

Understanding Welding Rods for PVC An Essential Guide

Welding is a critical process in various industries, especially in the manufacture and repair of plastic materials. Among these materials, Polyvinyl Chloride (PVC) stands out due to its durability, versatility, and cost-effectiveness. However, welding PVC requires the right tools and techniques to ensure a strong, reliable bond. One of the most crucial elements of this process is the choice of welding rods specifically designed for PVC applications.

What are Welding Rods for PVC?

Welding rods for PVC are specialized materials used to join PVC components together through a technique called thermoplastic welding. This process involves heating the welding rod and the edges of the PVC parts until they soften, allowing them to fuse together as they cool. The right choice of welding rods plays a significant role in the strength and longevity of the welded joint.

Types of PVC Welding Rods

There are primarily two types of PVC welding rods available in the market extruded rods and molded rods.

1. Extruded PVC Welding Rods These rods are created by forcing PVC material through a die, resulting in long, continuous lengths of consistent diameter. Extruded rods are commonly used due to their availability in various sizes and shapes, making them suitable for different welding scenarios.

2. Molded PVC Welding Rods These rods are formed using a molding process that allows for customized shapes and sizes. Molded rods offer the advantage of being specifically designed for particular applications, providing a tailored solution for complicated joints or repairs.

Choosing the Right Welding Rod

When selecting a welding rod for PVC, several factors should be considered

1. Compatibility Ensure that the welding rod is compatible with the type of PVC being used. Different grades of PVC, such as rigid or flexible, may require specific rods tailored to their composition.

2. Diameter and Length Depending on your project needs, choose the appropriate diameter and length of the welding rod. Smaller diameters can be useful for delicate applications, while thicker rods provide more strength for heavier-duty tasks.

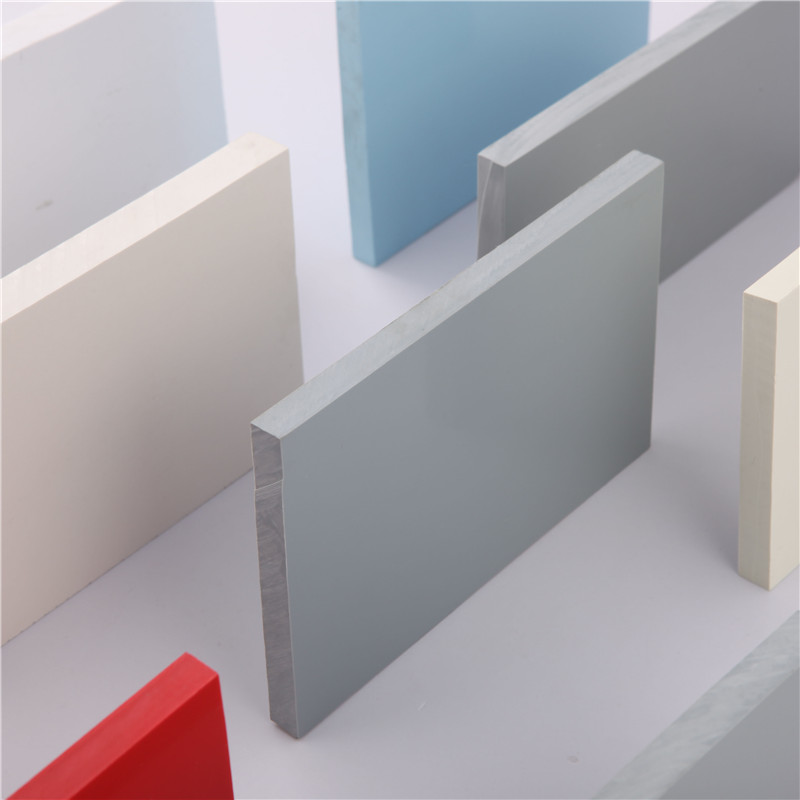

3. Color Matching For aesthetic applications, consider the color of the welding rod. Many manufacturers offer rods in various colors, allowing for a more seamless visual integration with the PVC parts being welded.

welding rods for pvc

Applications of PVC Welding Rods

PVC welding rods are used across a multitude of industries. Some common applications include

- Construction In building and construction, PVC is often used for piping systems, siding, and roofing materials. Welding rods can effectively join these components, ensuring a watertight and durable assembly.

- Aquaculture PVC is widely utilized in fish farming and aquaculture tanks. Using welding rods to construct or repair tanks ensures a robust barrier against leaks, which is vital for maintaining a healthy aquatic environment.

- Signage and Displays PVC is a popular choice for creating signage and display boards. The aesthetic appeal can be enhanced through precise welding techniques using color-matched rods.

Techniques for Welding PVC

The application of welding rods for PVC involves specific techniques to achieve optimal results

1. Preparation Clean the surfaces to be welded thoroughly. Any dirt or grease can significantly affect the quality of the weld.

2. Heating Use a heat gun or welding machine to heat the PVC edges and the welding rod. The temperature must be carefully controlled to avoid damaging the material.

3. Fusing Once the PVC and rod reach the appropriate temperature, they are brought together, allowing the softened materials to fuse. Applying slight pressure during this step helps create a stronger bond.

4. Cooling Allow the weld to cool undisturbed. Quick cooling may lead to weaknesses, so patience is key.

Conclusion

Using the right welding rods for PVC applications is essential for achieving high-quality, durable joints. With proper knowledge of the types of rods available, their applications, and the correct techniques, professionals can enhance their welding projects' efficiency and effectiveness. Whether in construction, aquaculture, or signage, mastering the use of PVC welding rods opens the door to endless possibilities in various industries. Proper training and adherence to best practices will ensure that these materials serve their purpose well, contributing to robust and lasting solutions.

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025