Yan . 24, 2025 05:13 Back to list

HDPE double wall corrugated pipe

In the dynamic landscape of modern industry, the selection of quality industrial pipe fittings is crucial for ensuring seamless operations across various sectors such as oil and gas, chemical processing, and manufacturing. Such fittings are not merely components of piping systems; they are the linchpins of operational integrity, bearing the brunt of pressure, temperature, and the corrosive nature of different materials flowing through the pipes. To navigate this intricate part of industrial engineering, both expertise and a nuanced understanding of the key performance attributes of pipe fittings are imperative.

Authoritativeness in the industry equates to not only knowing which types of fittings suit a particular application but also having insights backed by empirical evidence and case studies. Industry leaders often participate in forums and networks that share the latest innovations and testing methods for pipe fittings, ensuring they stay at the forefront of technological advancements. These insights provide a broader view of the pitfalls and best practices associated with various materials and fitting types, thus strengthening the decision-making process. Trustworthiness is built through the consistency of delivering high-performance solutions tailored to specific industrial needs. This entails a thorough vetting process of manufacturers, ensuring they adhere to international standards such as ISO and ASME, thus certifying the reliability and safety of their products. Quality assurance processes, such as non-destructive testing and certifications of compliance with environmental and safety regulations, are markers of reliable suppliers. Furthermore, trust in industrial settings also involves transparent communication regarding the lifecycle and maintenance requirements of the pipe fittings. End-users benefit significantly from this clarity, ensuring optimal upkeep and reducing downtime caused by premature fitting failures. Preventive maintenance schedules informed by expert advice can preempt potential issues, thus sustaining continuous operations and safeguarding against costly disrupts. In conclusion, the realm of industrial pipe fittings is not just a focus on mere components but a deep dive into the orchestrated performance of complex industrial systems. By leveraging a well-rounded understanding that balances experience, expertise, authoritativeness, and trustworthiness, industrial entities can optimize their piping installations, ensuring not only operational efficiency but also long-term reliability and safety. This nuanced approach ultimately spells the difference between thriving industrial operations and those that falter under the pressures of inadequate system components.

Authoritativeness in the industry equates to not only knowing which types of fittings suit a particular application but also having insights backed by empirical evidence and case studies. Industry leaders often participate in forums and networks that share the latest innovations and testing methods for pipe fittings, ensuring they stay at the forefront of technological advancements. These insights provide a broader view of the pitfalls and best practices associated with various materials and fitting types, thus strengthening the decision-making process. Trustworthiness is built through the consistency of delivering high-performance solutions tailored to specific industrial needs. This entails a thorough vetting process of manufacturers, ensuring they adhere to international standards such as ISO and ASME, thus certifying the reliability and safety of their products. Quality assurance processes, such as non-destructive testing and certifications of compliance with environmental and safety regulations, are markers of reliable suppliers. Furthermore, trust in industrial settings also involves transparent communication regarding the lifecycle and maintenance requirements of the pipe fittings. End-users benefit significantly from this clarity, ensuring optimal upkeep and reducing downtime caused by premature fitting failures. Preventive maintenance schedules informed by expert advice can preempt potential issues, thus sustaining continuous operations and safeguarding against costly disrupts. In conclusion, the realm of industrial pipe fittings is not just a focus on mere components but a deep dive into the orchestrated performance of complex industrial systems. By leveraging a well-rounded understanding that balances experience, expertise, authoritativeness, and trustworthiness, industrial entities can optimize their piping installations, ensuring not only operational efficiency but also long-term reliability and safety. This nuanced approach ultimately spells the difference between thriving industrial operations and those that falter under the pressures of inadequate system components.

Share:

Latest news

-

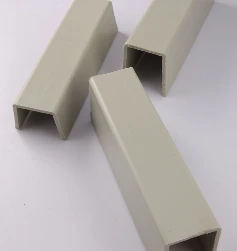

PP U-channel: Chemical-Resistant, Lightweight & Durable

NewsAug.10,2025

-

Transparent PVC Pipe: Clear Flexible Tubing for Fluids

NewsAug.09,2025

-

Durable PP Rigid Sheet: Versatile & High-Quality Plastic Panels

NewsAug.08,2025

-

Premium Glossy PP Rigid Sheet – Durable & Versatile

NewsAug.07,2025

-

High-Quality HDPE Sheet | Durable Plastic Panels

NewsAug.06,2025

-

High-Precision PVC Rigid Sheets for Vacuum Forming | AI-Optimized

NewsAug.05,2025