Noy . 07, 2024 09:25 Back to list

Exploring Various Types of Industrial Pipe Fittings and Their Applications

The Importance of Industrial Pipe Fittings in Modern Infrastructure

In the realm of industrial applications, pipe fittings play a crucial role in ensuring the efficient and safe transportation of fluids and gases. From oil refineries to chemical plants, the demand for high-quality industrial pipe fittings has surged as industries strive to optimize their processes and maintain safety standards. This article explores the types, applications, and significance of industrial pipe fittings in modern infrastructure.

Understanding Pipe Fittings

Pipe fittings are essential components used to connect, redirect, and terminate pipes within various systems. They come in various shapes, sizes, and materials, including steel, copper, PVC, and more. Each type of fitting serves a specific purpose, whether it’s to change the direction of flow, control the flow rate, or connect different sizes of pipes.

One of the most common types of industrial pipe fittings includes elbows, which are used to change the direction of the flow. They are available in various angles, typically 90-degree or 45-degree, allowing for versatile configurations in piping systems. Another important type is tees, which allow for branching pipelines in different directions. Couplings and adapters are also widely used to join two pipes together, ensuring a secure and leak-free connection.

Applications of Industrial Pipe Fittings

Industrial pipe fittings are used across a wide range of sectors, including

1. Oil and Gas In the oil and gas industry, the transportation of crude oil, natural gas, and refined products heavily relies on robust piping systems. Industrial fittings are critical for fitting together various pipeline segments, ensuring that the liquids and gases are transported safely.

2. Water Supply and Wastewater Treatment Municipal water systems and wastewater treatment plants utilize pipe fittings to manage the distribution and treatment of water. Here, the fittings must withstand corrosive environments and varying pressures.

industrial pipe fittings

3. Chemical Processing The chemical industry uses industrial pipe fittings to transport harsh chemicals and fluids safely. The materials for these fittings are often selected based on their resistance to chemical corrosion and pressure, making safety and reliability paramount.

4. Pharmaceuticals In the pharmaceutical sector, maintaining strict hygiene and safety standards is crucial. Pipe fittings play an essential role in ensuring that the transfer of materials does not contaminate products, often made from specialized stainless steels or sanitary materials.

The Significance of Quality in Pipe Fittings

The quality of pipe fittings cannot be overstated. Faulty or substandard fittings may lead to leaks, system failures, and hazardous situations, which can have dire financial and environmental consequences. Therefore, manufacturers must adhere to international quality standards, such as ASTM (American Society for Testing and Materials) and ANSI (American National Standards Institute), to ensure the reliability of their products.

Moreover, technological advances have led to improved manufacturing processes, resulting in enhanced materials and designs that withstand extreme pressure and temperatures. Innovations in 3D modeling and computer simulations also allow engineers to design more efficient and effective piping systems tailored to specific industrial needs.

Future Trends in Industrial Pipe Fittings

Looking ahead, the industrial pipeline fittings market is poised for growth driven by increased industrialization, urban development, and infrastructure investments worldwide. Additionally, there is a growing emphasis on sustainability, prompting industries to adopt greener solutions. This includes the development of eco-friendly materials and efficient manufacturing practices that minimize waste.

Furthermore, the integration of smart technologies, such as IoT (Internet of Things) in pipe systems, will enhance monitoring and maintenance, potentially reducing risks associated with leaks and failures.

In conclusion, industrial pipe fittings serve as the backbone of modern infrastructure, enabling the seamless flow of essential resources across various industries. Their importance cannot be underestimated, as they not only facilitate operations but also contribute to safety and environmental sustainability. As technology evolves and industries expand, the demand for high-quality, reliable pipe fittings will continue to grow, signaling a bright future for this critical component of industrial systems.

-

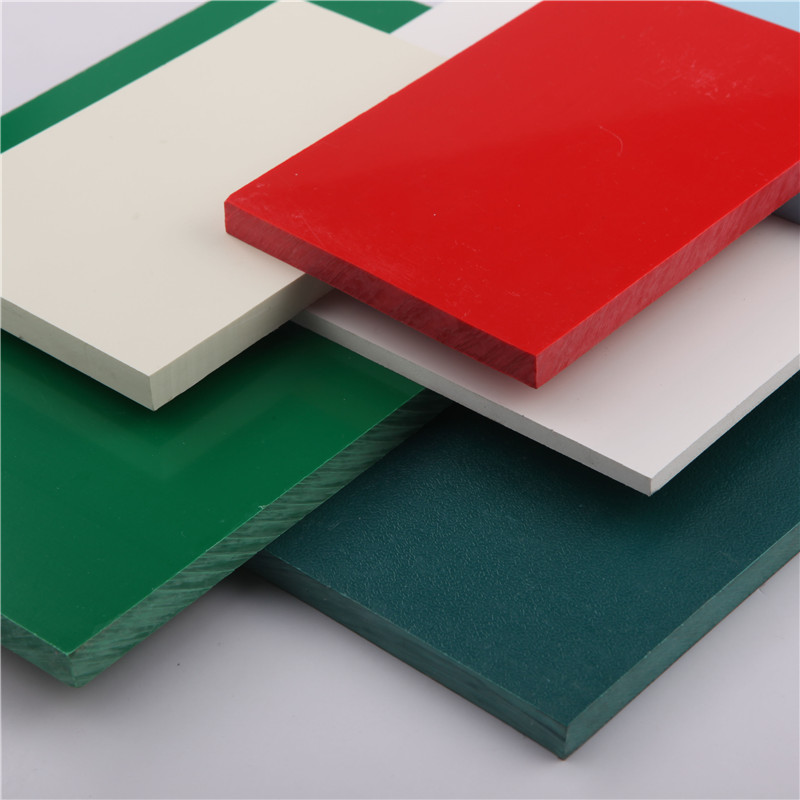

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025