Jan . 31, 2025 04:42 Back to list

HDPE water supply pipe

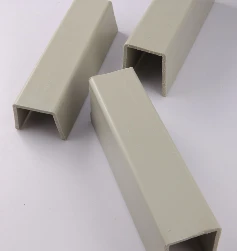

PPR pipe fittings have increasingly become the cornerstone of modern plumbing systems due to their superior durability, resistance to chemical substances, and efficiency in various applications. As a professional with years of experience in the field of plumbing engineering and sustainable construction, the following insights aim to elevate your understanding of PPR pipe fittings and their substantial advantages.

In terms of installation, PPR pipes and fittings exhibit remarkable efficiency. Their lightweight nature simplifies handling and reduces labor costs. Furthermore, the material's flexibility aids in reduced installation time, specifically in projects requiring complex pipe layouts. Authoritative voices in the construction industry, ranging from architects to civil engineers, advocate for the use of PPR pipe fittings in infrastructures that demand robust and versatile piping systems. Their consistent performance under adverse conditions, coupled with cost-effectiveness, positions PPR fittings as a trusted component in global plumbing standards. For property owners and facility managers, the trustworthiness of PPR fittings lies in their proven track record. With a shelf life that often surpasses 50 years, these fittings minimize the need for frequent maintenance or replacements, effectively reducing long-term operational expenses. The evolution of PPR technology continues to shape advanced plumbing solutions, integrating smart systems that monitor and manage water usage efficiently. Such innovations further enhance the application scope of PPR fittings, indicating their lasting impact on modern engineering solutions. To conclude, the choice of PPR pipe fittings presents a compelling proposition for construction projects necessitating reliability, sustainability, and cost-efficiency. Their intrinsic attributes and proven excellence across various domains speak volumes of their enduring relevance and authority in the plumbing industry. This makes PPR pipe fittings not only a modern solution but an indispensable ally in building the infrastructure of the future.

In terms of installation, PPR pipes and fittings exhibit remarkable efficiency. Their lightweight nature simplifies handling and reduces labor costs. Furthermore, the material's flexibility aids in reduced installation time, specifically in projects requiring complex pipe layouts. Authoritative voices in the construction industry, ranging from architects to civil engineers, advocate for the use of PPR pipe fittings in infrastructures that demand robust and versatile piping systems. Their consistent performance under adverse conditions, coupled with cost-effectiveness, positions PPR fittings as a trusted component in global plumbing standards. For property owners and facility managers, the trustworthiness of PPR fittings lies in their proven track record. With a shelf life that often surpasses 50 years, these fittings minimize the need for frequent maintenance or replacements, effectively reducing long-term operational expenses. The evolution of PPR technology continues to shape advanced plumbing solutions, integrating smart systems that monitor and manage water usage efficiently. Such innovations further enhance the application scope of PPR fittings, indicating their lasting impact on modern engineering solutions. To conclude, the choice of PPR pipe fittings presents a compelling proposition for construction projects necessitating reliability, sustainability, and cost-efficiency. Their intrinsic attributes and proven excellence across various domains speak volumes of their enduring relevance and authority in the plumbing industry. This makes PPR pipe fittings not only a modern solution but an indispensable ally in building the infrastructure of the future.

Share:

Next:

Latest news

-

Transparent PVC Pipe: Clear Flexible Tubing for Fluids

NewsAug.09,2025

-

Durable PP Rigid Sheet: Versatile & High-Quality Plastic Panels

NewsAug.08,2025

-

Premium Glossy PP Rigid Sheet – Durable & Versatile

NewsAug.07,2025

-

High-Quality HDPE Sheet | Durable Plastic Panels

NewsAug.06,2025

-

High-Precision PVC Rigid Sheets for Vacuum Forming | AI-Optimized

NewsAug.05,2025

-

Durable PVC-M Water Supply Pipes | 60-Year Life

NewsAug.04,2025